REINFORCED CEMENT CONCRETE (RCC) (NP2/NP3) PIPES

- (a) The pipes should be with reinforcement and should be of the specified class as per IS : 458. The reinforced cement concrete pipes shall be manufactured by centrifugal (or spun) process while un–reinforce cement concrete pipes by spun or pressure process.

- All pipes shall be true to shape, straight, perfectly sound and free from cracks and flaws.

- The external and internal surface of the pipes shall be smooth and hard. The pipes shall be free from defects such as imperfect grading due to improper aggregate mixing or moulding.

CONCRETE FOR REINFORCED CEMENT CONCRETE (RCC) (NP2/NP3) PIPES

Concrete used for the unreinforced and reinforced concrete pipes and collars should not be leaner than 1:2:4 (1 cement : 2 coarse sand : 4 graded stone aggregate).

The maximum size of aggregate should not exceed one third of the thickness of the pipe or 200 mm whichever is smaller. The reinforcement in the reinforced concrete pipes should not present throughout the complete length of the pipe.

The circular and longitudinal reinforcements should be so much strong so that it have adequate to withstand the hydrostatic pressure and further bending stresses due to the weight of water when running full across a span equal to the length of pipe plus three times its own weight.

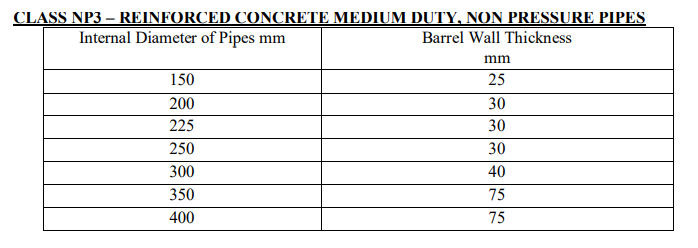

CLASS NP2 – REINFORCED CONCRETE LIGHT DUTY, NON PRESSURE PIPES

| Internal Diameter of Pipes Nominal mm | Barrel Wall Thickness Mm |

| 80 | 25 |

| 100 | 25 |

| 150 | 25 |

| 200 | 25 |

| 225 | 25 |

| 250 | 25 |

| 300 | 30 |

| 350 | 32 |

| 400 | 32 |

| 450 | 35 |

| 500 | 35 |

| 600 | 45 |

REINFORCED CEMENT CONCRETE (RCC) (NP2/NP3) PIPES TRENCHES EXCAVATION

The trenches excavation should be done so that the pipes should be laid with the required alignment and also at a required depth.

- Cover of pipes should be measured from top of pipe to the surface of the ground.

- The bed of the trench, if in soft or made up earth, shall be well watered and rammed before laying the pipes and the depressions, if any, shall be properly filled with earth and consolidated in 20 cm layer.

- If the trench bottom is extremely hard or rocky or loose stony soil, the trench should be excavated at least 150 mm below the trench grade. Rocks, stone, any rocky or hard substances from the bottom of the trench should be removed and the trench should be filled back by the selected fine earth or sand (or finesand if fine soil or sand is not available locally) and compacted so as to provide a smooth bedding for the pipe.

- After the excavation of the trench is completed, hollows shall be cut at the required position to receive the socket of the pipes and these hollows should be of sufficient depth to ensure that the barrels of the pipes should rest throughout their entire length on the solid ground and spaces left for jointing the underside of the pipe joint. pipe socket holes should be refilled with sand as soon as the jointing of the pipe is complete.

- Roots of trees within a distance of about 0.5 meter from the side of the pipe line shall be removed or killed.

- The excavated materials shall not be placed within 1 meter or half of the depth of the trench, whichever is greater, from the edge of the trench. The materials excavated shall be separated and stacked so that in refilling that may be re-laid and compacted in the same order to the satisfaction of the Engineer-incharge.

- No water should be present in the trench it should be kept free from water. Shoring and timbering shall be provided wherever required. Excavation below water table shall be done after rewatering the trenches.

- Where the pipe line or drain crosses an existing road, the road crossing shall be excavated half at a time, the 2nd half being commenced after the pipes laying and trench refilling is complete.

- All types, water main cables, etc. found during the the course of excavation should be carefully protected and supported. Care should be done properly to protect the electrical and communication cable which found during course of excavation, removal of which, if required.

REINFORCED CEMENT CONCRETE (RCC) (NP2/NP3) PIPES Laying Method

Pipes shall be lowered into the trench carefully. Mechanical appliances may be used, where necessary, pipes shall be laid in straight lines or with easy curves and true to line and gradient as specified.

Laying of pipes should be done as up grade of a slope. In the pipes spigot end socket joints, the socket ends shall have face up stream. In the case of pipes with joints to be made with loose collars the collars shall be slipped on before the next pipe is laid.

In case where the foundation conditions are unusual such as the proximity of trees for holes, under existing or proposed tracks, manholes etc. the pipe shall be encased around in 150 mm thick cement concrete 1:5:10 ( 1 cement : 5 fine sand : 10 graded stone aggregate 40 mm nominal size).

In case where the natural foundation is inadequate the pipes shall be laid either in concrete cradle supported on proper foundation or on any other suitably designed structure. If a concrete bedding is used, the depth of concrete below the bottom of the pipe shall be at one forth of the internal diameter of the pipe subject to the minimum of 100 mm and a maximum 300 mm.

The concrete should extend up the sides of the pipe at least to a distance of one forth of the outside diameter for pipes 300 mm and over in diameter. The pipe should be laid in this concrete before the settling time of concrete.

Pipes laid in trenches in earth shall be bedded evenly and as far up to the haunches of the pipe as to safety transmit the lead expected from the back sill through the pipe to the bed.

This shall be done either by excavating the bottom of the trench to fit the curve of the pipe or by compacting the earth underground the curve of the pipe to from an even bed.

When the pipe is to belaid in a trench containing rock hard clay, shale or other hard material the space below the pipe shall be excavated and filled with an equalizing bed of concrete, sand or compacted earth. Pipe should not be laid directly on such hard material.

Method of Installation of Kerbstone| Rate Analysis for Cost of Kerbstone

![]() REINFORCED CEMENT CONCRETE (RCC) (NP2/NP3) PIPES JOINTING

REINFORCED CEMENT CONCRETE (RCC) (NP2/NP3) PIPES JOINTING

Rigid Spigot and Socket Joint :

The spigot of each pipe shall be fitted well into the socket of the pipe previously laid and adjusted in the correct manner.

The opening of the joint shall be filled with stiff mixture of cement mortar in the proportion of 1:2 (1 cement : 2 fine sand) which shall be rammed with caulking tool. After a day’s work the newly made joint shall be cured.

Rigid Collar Joint :

The two pipes should be butted against each other and adjusted in correct position. The collar should be slipped over the joint, covering equally both the pipes in proper manner . The space between pipe should be filled with stiff mixture of cement mortar 1:2 (1 cement : 2 fine sand) which should be rammed. After a day’s work any extraneous materials shall be removed from the inside of the pipe and the newly made joint shall be cured.

REINFORCED CEMENT CONCRETE (RCC) (NP2/NP3) PIPES MEASUREMENTS

The lengths of pipes shall be measured in running meters nearest to a cm as laid or fixed, from inside of one manhole to the inside of the other manhole.

The length shall be taken along the center line of the pipes over all fittings such as bends, collars, junctions, etc. which shall not be measured separately.

Excavation, refilling, shoring and timbering in trenches, and cement concreting wherever required is measured separately under relevant items of work.

REINFORCED CEMENT CONCRETE (RCC) (NP2/NP3) PIPES RATE Analysis

The rate shall include the cost of materials and labour involved in all the operations described above.

If you have any query – connect us

Leave a Reply