wet mix macadam (wmm) in Road Construction

Wet Mix Macadam laying method contains of laying spreading and compacting of clean, crushed, well-graded granular materials on a prepared and Granular sub-Base. For Wet Mix Macadam material is well mixed with water and then rolled to a dense mass. It should be laid on one or more layers as per line and level, grade and cross section shown in the good for Construction drawing .

Wet Mixed Macadam (WMM) Base thickness of single compacted should not be less than 75 mm. WMM shall be laid in layers of 75mm or 100mm as per thickness.

Wet Mix Macadam (WMM) technical specifications

Wet Mix Macadam (WMM) Base Preparation

After the layer of GSB Sub-Base has been laid , then line and level are done to start the Wet Mix Macadam base layer which is also called as WMM Base. Pegs are to be provided at regular intervals on the side of the road edge , on those places blade of grader should not disturb the peg while mixing of the Base materials. On each peg’s or bhurji or kerbstone at corners top level of Base layer is marked with the paint or marker. The chainage boards and working bench mark should be kept outside the range of construction areas to avoid breakage and damage of those bench marks.

Wet Mix Macadam Construction Material

- Aggregate for Wet Mix Macadam Construction

- Coarse aggregate shall be crushed stone or crusher run as per IRC 109 or clause 406.2.1 of MORT&H specification.

Physical requirement for Wet Mix Macadam Construction

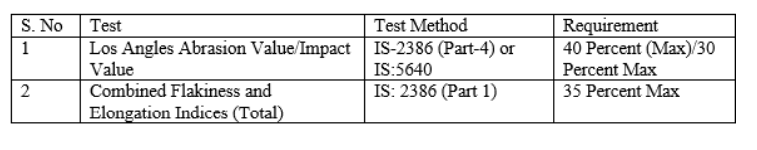

The part of the aggregates should be made by the integrated crushing and screening plant (Impact or Cone type), crushing shall be done in at least two stages. The part of material which is passing through 4.75mm sieve should also be crusher run screening only. The aggregate used for the WMM Preparation should conform to the physical requirements set forth in Table 400-12 of MORT&H. or IRC 109 clause 3.1.1

If the water absorption value test of coarse aggregate is greater than 2 per cent, the soundness test should be done on the materials delivered to site for WMM Construction.

Table 400-12 Physical Requirement of coarse aggregate for Wet Mix Macadam for Sub-base/Base Courses

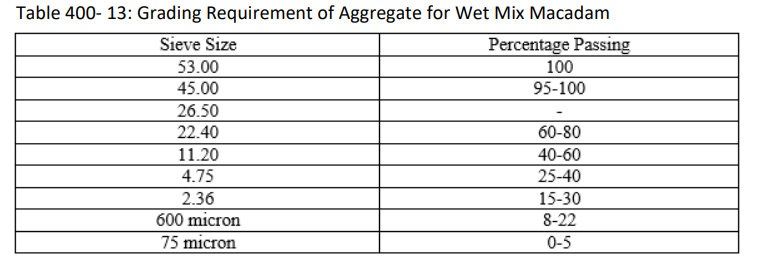

Grading Requirement for for Wet Mix Macadam Construction

The aggregate shall conform to the grading given in table 406.2.1.2 of technical specification or IRC 109 -2015. Material finer than 425 micron, should have the Plasticity Index (PI) less than 6. The final gradation approved within these limits shall be well graded from coarse to fine and should not differ from the lower limit on one sieve to the higher limit of adjacent sieve or vice versa.

Equipment or tools for for Wet Mix Macadam Construction

The following equipment shall be carried out for the WMM

1. Wet Mix Macadam Plant

2. Dumper / Tippers.

3. Vibro Roller (80 to 100 KN)

4. Water Tanker

5. Paver capable of paving more than 9 meter width.

6. Survey kit / instrument

Method of wet mix macadam (wmm) in Road Construction

Preparation of wet mix macadam (wmm) WMM Base Provision of lateral confinement of aggregates- Proper arrangement shall be made for the lateral confinement of wet mix during laying. wet mix during laying should be done by laying materials on neighbouring shoulder along with that of WMM layer. All the basic three process preparation of mix for WMM, spreading of mix for WMM and compaction for WMM are done sequentially. The sequence of WMM method should be followed same as described in clause: 406.3.3 of MORT&H.

Preparation of wet mix macadam (wmm)

Wet mix Macadam should be prepared by WMM mixing plant having provision for controlled addition of water and forced/positive mixing arrangement. Moisture required for Wet mix Macadam mixing shall be determined in accordance with IS: 2720 (Part 8) after replacing the aggregate fraction retained on 22.4 mm sieve with materials of passing from 22.4 and retained on 4.75 mm. when we add water, then evaporation loss should also be taken into account. The Wet mix Macadam mixed material should be uniformly wet and no segregation shall be allowed.

Laying of wet mix macadam (wmm) mix

Immediately after mixing, the aggregate should be spread uniformly and evenly upon the GSB layer. Materials should not be dumped in heap and also not on the a partly completed stretch. The first layer will be laid by motor grader and the second layer mix should be spread by a WMM paver finisher capable of paving minimum 4.5m to 9.0m width. No segregation of materials is allowed. The aggregates should be of uniform size with no quantity of fine materials.

wet mix macadam (wmm) Compaction

After the Wet Mix Macadam mix has been laid on site to the required thickness, grade and camber, then compaction is carried out with suitable roller to the full depth.

For a Wmm thickness up to 200mm in a one layer, compaction should be done by vibratory roller of 80 to 100 KN static weights with plain drum or equivalent capacity roller. Rolling is done from down area towards upper area in a longitudinally motion for the portion having unidirectional cross fall and super elevation. Each pass of the roller should uniformly overlap area not less than one third of the area in the previous pass. During rolling, slopes and Levels should be checked and any high spot or depressions, which should be corrected by adding or removing fresh materials. The

speed of roller shall not exceed 5km/h. Rolling through the roller should be continued till the density of the layer is achieved 98% of the Maximum Dry Density. The Field Density can be calculated through Core cutting method.

Rolling should be stopped when the WMM layer is soft or yielding or when it causes a wave like motion. If level difference or irregularities formed during rolling, it exceeds 12 mm when tested along 3 metre straight edge, the surface should be immediately loosened and premixed materials added

or removed as required before rolling once again. unmixed material should not be permitted to make up the depressions formed during rolling.

Opening to traffic for wet mix macadam (wmm)

After testing for the compaction of road & level is checked of WMM course the road should be allowed to dry for 24 hours. No vehicular traffic Movement should be allowed on the finished WMM surface till it has dried and covered with wearing course.

Tests for Granular WMM Base: Post Construction

Tolerance in Surface Level : +10 mm

permissible undulation for the 3 m straight edge is of 8 mm

no. of undulations permitted in any 300 m length, exceeding 12 mm: 20

Checking of quality of materials and works should be in accordance to section 900 of MORT&H.

Vehicles tracks should be moist to prevent flying of dust particles from the vehicle movement

Flexible Road Construction Method Process Step by Step

Rectification of defective construction in wet mix macadam (wmm)

Where the surface irregularity of the WMM sub-base course exceeds the tolerances specified or where the course is otherwise defective due to sub-grade soil mixing with the aggregates, the layer to its complete thickness should be scarified over the affected area, it should be reshaped with added material or removed and replaced with fresh wmm material as required, and recompacted. The area treated in the WMM Water Mixed Macadam should not be less than 10 Sqm. Depressions formed during WMM Process should not be filled up with screenings and binding materials.

Measurements of wet mix macadam (wmm) for Billing

The length and breadth should be measured to the nearest centimeter and thickness to the nearest half centimeter. The consolidated cubical contents shall be calculated in cubic meters correct to two places of decimals.

If you have any query on the above article wet mix macadam (wmm) in Road Construction , Please feel free tocomment.

Leave a Reply