What is meant by potable water?

Water used for both mixing and curing shall be free from injurious amounts of deleterious materials. When we prefer the term potable water then it means that water which is safe from drinking. Potable water used in construction should be free from high level quantities of alkalis, acid, oils, salt, sugar, organic materials, vegetable growth and other substances. Water is one of the most important aspects of Construction but people generally don’t give importance to it that can lead to bad quality of concrete. Potable water is good for mixing and curing concrete.

Water Quality for Building Construction as per IS 456:2000

In case of doubt, the suitability of water for making concrete shall be ascertained by the compressive strength and initial setting time test specified in IS-456 -2000.

Tests of water quality for concrete construction

1. Before going for the testing of sample of water it should be checked that , it shall be same water proposed to be used for concreting, due account being paid to seasonal variation. The sample shall not receive any treatment before testing other than that used in the regular supply of water proposed for use in concrete. The sample shall be stored in a clean container which should be washed by the similar water which is tested well for construction.

2. If we talk about the Average 28 day’s compressive strength of at least three 15 cm concrete cubes prepared with water tested before for the concrete or portable water to be used shall not be less than 90% of the average strength of three similar concrete cubes prepared with distilled water.

3. The initial setting time or test block made with the appropriate set cement and the water proposed to be used shall not be less than 30 minutes and shall not differ by more than plus minus 30 seconds form the initial setting time of control test block prepared with the appropriate test cement and distilled water. The test blocks shall be prepared and tested in accordance with the requirements of IS 4031.

Where water can be shown to contain an excess of acid, alkali sugar or salt, engineer may refuse to permit its use.

The following concentrations represent the maximum permissible values for water used for Construction Purpose:

i) To neutralize 100 ml sample of water, using phenolphthalein as indicator, it should not require more than 5 ml of 0.2 normal Noah. If you want to clarify the details you can clear from the details of test shall be as given in IS 3025 (part 22).

ii) To neutralise 100 ml sample of water using Mix Indicator as an indicator, it should not require more than 25 ml of 0.02 normal H2SO4. The details of test shall be given in IS 3025 (part 23).

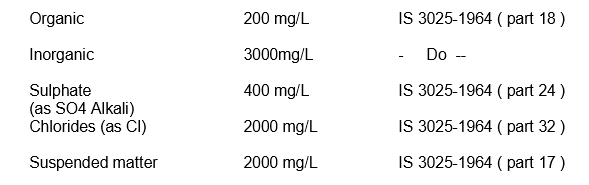

iii) Percentage of solids when tested in accordance with the method indicated below shall not exceed the following:

Permissible Limits for Type of Solid in water for Construction work

If you want to get the descriptive knowledge of the Water Quality for Building Construction as per IS 456:2000 then you can visit the link attached to that, it will guide you in detail.

What is the meaning of aggregate|what is coarse aggregate

If you have any query about the article Water Quality for Building Construction as per IS 456:2000 then just leave your comment below, dint forget to like our page to get the best all the updated news about civil engineering.

Leave a Reply