What is Concrete Form work?

The Concrete Formwork shall consist of shores, bracings, sides of beams and columns, bottom of slabs etc, including ties anchors, hangers inserts etc, complete which shall be properly designed and planned for the work. Wedge may be used at the top or bottom of timber shores but not at both ends to facilitate vertical adjustment or dismantling of the formwork.

What is Design of form work?

The design of the formwork as well as its construction shall be the responsibility of Engineer. The design shall take into account the entire load vertical and lateral that the forms will be carrying live and vibration loadings.

Type of form work| Types of Shuttering

Formwork may be of timber, plywood, metal, plastic or concrete. For special finishes the formwork may be lined with plywood, steel sheets oil tempered hard board etc

What are Form work requirements?

i) Forms shall conform to the shapes, lines, grades and dimensions including camber of the concrete as called for on the drawings. Ample studs, braces, ties, straps, etc. shall be used to hold the forms in proper position without any distortion whatsoever until the concrete is set sufficiently to permit removal of forms. Forms shall be strong enough to permit the use of immersion vibrators. In special cases form vibrators may also be used. The shuttering shall be close boarded. Timber shall be well seasoned, free from sap, shakes, loose knots, worm holes, warps or other surface defects in contact with concrete. Faces coming in contact with the concrete shall be free from adhering grout, plaster, and paint, projecting nails, splits or other defects. Joints shall be sufficiently tight to prevent loss of water or any fine material from concrete.

ii) Plywood shall be used for exposed concrete surfaces; where called for Sawn and wrought timber may be used for unexposed surfaces. Inside faces of forms for concrete surfaces, these are to be rubbed finished shall be planed to remove irregularities or uneven ness in the face. Formwork with linings shall be permitted.

iii) All new and used form timber shall be maintained in a good condition with respect to shape, strength, rigidity, water tightness, smoothness and cleanliness of surfaces.

iv) Shores supporting successive members shall be placed directly over those below or be so designed and placed that the load will be transmitted directly to them. Trussed supports shall be provided for shores that cannot be secured on adequate foundations.

v) Formwork, during any stage of construction showing signs of distortion or distorted to such a degree that the intended concrete work will not conform to the exact contours indicated on the drawings, shall be repositioned and strengthened. Poured concrete affected by the faulty formwork, shall be removed completely and the formwork be corrected prior to placing of new concrete.

vi) Excessive construction camber to compensate for shrinkage, settlement may impair the structural strength of members and shall not be permitted.

vii) Forms shall be so designed that their removal will not damage the concrete. Face formwork shall provide true vertical and horizontal joints, conform to the architectural features of the structure as to location of joints.

viii) Where exposed smooth or rendered concrete finishes are required the forms shall be constructed with special care so that the resulting concrete surfaces require a minimum finish.

What is Form work for Exposed Concrete Surfaces?

i) Where it is desired, directed or shown on the drawings to have original fair face finish of concrete surface without any rendering or plastering, formwork shall be carried out by using wood planks, plywood or steel plates of approved quality.

ii) The contractor shall use one type of material for all such exposed concrete faces and the forms shall be constructed so as to produce uniform and consistent texture and pattern on the face of the concrete. Patches or forms for these surfaces will not be permitted. The formwork shall be placed so that all horizontal formworks are continuous across the entire surface.

iii) To achieve a finish which shall be free of board marks, the formwork shall be faced with plywood or equivalent material in large sheets. The sheets shall be arranged in an approved pattern. Wherever possible, joints between sheets shall be arranged to coincide with architectural features, sills, window heads or change in direction of the surface.

All joints between shuttering plates or panels shall be vertical or horizontal unless otherwise directed. Suitable joints shall be provided between sheets. The joints shall be arranged and fitted so that no blemish or mark is imparted to the finished surfaces.

iv) To achieve a finish which shall give the rough appearance of concrete cast against sawn boards, formwork boards unless otherwise stated shall be of 150 mm wide, securely jointed with tongue and grooved joints if required to prevent grout loss with tie rod positions and direction of boards carefully controlled. Sawn boards shall be set horizontally, vertically or at an inclination shown in the drawings. All bolt holes shall be accurately aligned horizontal and vertically and shall be filled with matching mortar recessed 5mm back from the surrounding concrete face.

v) Forms for exposed concrete surfaces shall be constructed with grade strips (the underside of which indicated top of pour) at horizontal construction joints, unless the use of groove strips is specified on the drawings. Such forms shall be removed and reset from lift to lift; they shall not be continuous from lift to lift. Sheeting of reset forms shall be tightened against the concrete so that the forms will not be spread and permit abruption irregularities or loss of mortar. Supplementary form ties shall be used as necessary to hold the reset forms tight against the concrete.

vi) For fair faced concrete, the position of through bolts will be restricted and generally indicated on the drawings.

vii) Chamfer strips shall be placed in the corners of forms for exposed exterior corners so as to produce 20 mm levelled edges except where otherwise shown in the drawings. Interior corners and edges at formed joints shall not be levelled unless shown on the drawings. Moulding for grooves, drip courses and bands shall be made in the form itself.

viii) The wood planks, plywood and steel plates used in formwork for obtaining exposed surfaces shall not be used for more than 3 times in case of wood planks, 6 times for plywood and 10 times for steel plates respectively.

ix) In order to obtain exposed concrete work of uniform colour it shall be necessary to ensure that the sand used for all exposed concrete work shall be of approved uniform colour. Moreover the cement used in the concrete for any complete element shall be from single consignment.

x) No exposed concrete surface shall be rendered or painted with cement or otherwise. Plastering of defective concrete as a means of achieving the required finish shall not be permitted, except in the case of minor porosity on the surface, the Engineer may allow a surface treatment by rubbing down with cement and sand mortar of the same richness and colour as for the concrete. This treatment shall be made immediately after removing the form work.

xi) The engineer shall also take all precautionary measures to prevent breaking and chipping of corners and edges of completed work until the building is handed over.

Bracing struts and props in Form work –

1.Shuttering shall be braced, strutted, propped and so supported that it shall not deform under weight and pressure of the concrete and also due to the movement of men and other materials. Bamboos shall not be used as props or cross bearers.

2.The shuttering for beams and slabs shall be so erected that the shuttering on the sides of the beams and under the soffit of slabs can be removed without disturbing the beam bottoms. Re-propping of beams shall not be done except when props have to be reinstated to take care of construction loads anticipated being in excess of the design load. Vertical props shall be supported on wedges or other measures shall be taken whereby the props can be gently lowered vertically while striking the shuttering. If the shuttering for a column is erected for the full height of the column, one side shall be left open and built up in sections as placing of concrete from the sides to limit the drop of concrete to 3M or as directed by engineer.

Form work Oil – Uses of Shuttering Oil for Form works

Care shall be taken to see that the faces of form wok coming in contact with concrete are perfectly cleaned and two coats of mould oil or any other approved material applied before fixing reinforcement and placing concrete. Such coating shall be insoluble in water, non-staining and not injurious to the concrete. It shall not become flaky or be removed by rain or wash water. Reinforcement and/or other items to be cast in the concrete shall not be placed until coating of the forms is complete; adjoining concrete surface shall also be protected against contamination from the coating material.

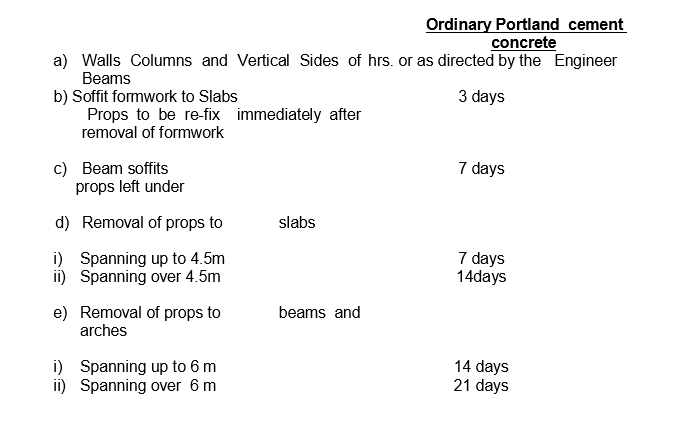

Time for removal of Shuttering -Concrete Form work Removal Time

In no circumstances shall forms be struck until the concrete reaches strength of at least twice the stress due to self-weight and any construction/erection loading to which the concrete may be subjected at the time of striking formwork.

How to repair cracks in concrete Surfaces| Concrete Crack Repair Guide

In normal circumstances (generally where temperatures are above 20 Deg. Cent.) forms may be removed after expiry of the following periods:-

Tie rods, clamps, form bolts etc. which must be entirely removed from walls or similar structures shall be loosened not sooner than neither 24 hours nor later than 40 hrs. After the concrete has been deposited. Ties, except those required to hold forms in place, may be removed at the same time. Ties, withdrawn from walls and grade beams shall be pulled towards the inside face cutting ties back from the faces of walls and grade beams will not be permitted.

Mode of Measurement of form work in construction| Mode of Measurement of Shuttering in construction

It shall be measured in Sq. M The actually shuttered area shall be measured and paid for.

For Example you have a slab of 4 meter in length , 3 Meter in width and have a depth of .15mm . Then shuttering will be calculated by = Length x width = 4×3= 12 Sqmm.

If you have any query about our article Types of form work in construction|Measurement of Concrete Form works. come up with your comments and if you are facing in calculation of any form work then contact me here – Vivek Mishra

Leave a Reply