How to Construct Circular Manhole| How to Construct Conical Manhole

Circular Manhole is of different types and sizes as required as per the specification shall be constructed in the sewer line at such places and to such levels and dimensions as shown in the drawings.

If we talk about the dimensions of the manhole, then size indicates the inside dimensions of the manhole.

Before the construction of the Manhole a bed of Plain cements concrete 1:2:4 (1 part cement: 2 part sand: 4 part agg of 40 mm nominal size). The thickness of the bed concrete generally varies from 100-150 mm.

Flexible Road Construction Method Process Step by Step

For the Circular Manhole or Conical Manhole Brick work cement mortar generally used is 1:5 (1 part cement: 5 part sand). The external joints of the brick masonry are to be finished smooth. The joints of the pipes with the masonry should be made perfectly leak-proof with cement concrete 1:2:4.

The brick walls of the manholes should have a plaster inside surface and up to full depth 12mm thick cement plaster 1:3 (1 part cement : 3 part sand ) and outside 19mm thick (C:M 1:3) finished smooth with a floating coat of neat cement, the balance outside surface to be pointed with cement mortar CM 1:2.

Brick work Manhole Channels and benching should be in cement concrete 1:2:4 (1 part cement: 2 part sand: 4 part graded stone aggregate).

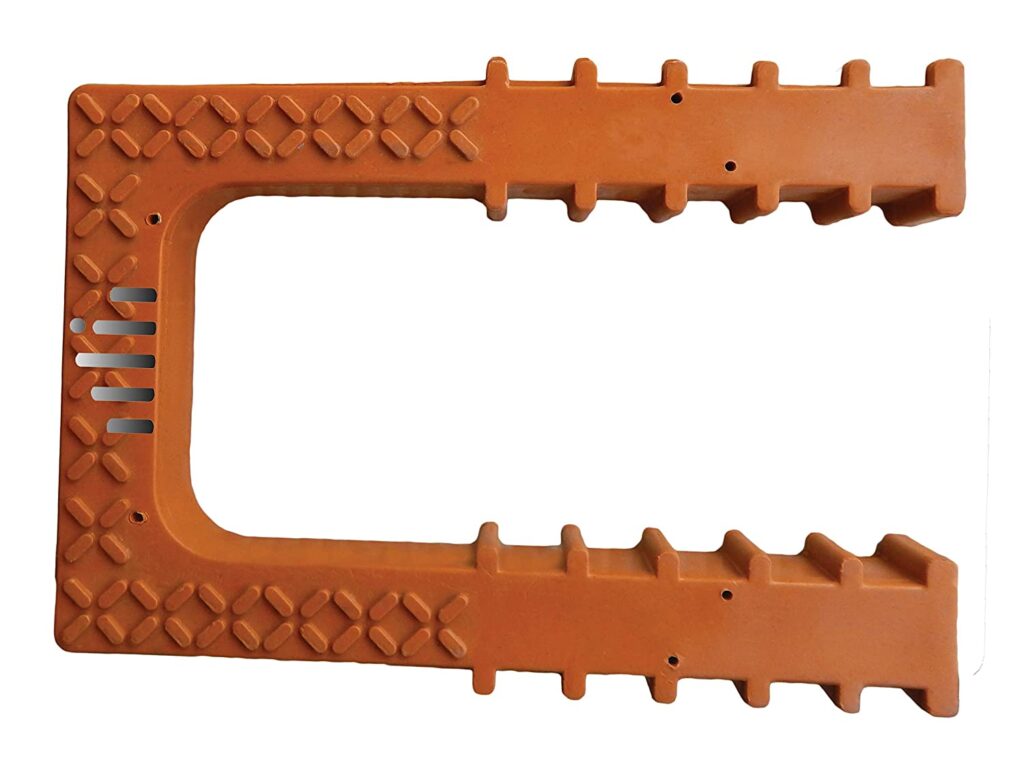

How to place the CI foot rest/ PVC Foot Steps?

If manholes are deeper than 1.0 m then it should be provided with CI foot rest/ PVC Foot Steps. CI foot rest/ PVC Foot Steps should be embedded 20 cm deep with 20x20x10 cm blocks of cement concrete M 15. The block with CI foot rest placed in its centre shall be cast-in-situ along with the masonry and the surface finished with 12 mm thick cement plaster 1:4 (1 part cement: 4 part sand) finished smooth.

Foot rests should be fixed 30 cm apart vertically and staggered laterally and shall project 10 cm beyond the surface of the wall. First foot rest from top should be 45 cm below the manhole cover.

Sewers of unequal sectional area shall not be joined at the same invert level in a manhole. The invert of the smaller sewer at its junction with main shall be, at a height at least 2/3 the diameter of the main, above the invert of the main. The branch sewer should deliver sewage in the manhole in the direction of main flow and the junction must be made with care so that flow in the main is not impeded.

No drains from house fittings e.g. GT, soil pipe etc. exceeding a length of 6m shall be connected unless it is inevitable.

Acid/alkali proof ceramic tiles/Mandana lining on the benching/internal walls up to desired height should be provided as per the details.

How to Calculate Brick work Quantity in a Circular Manhole

To Calculate Brick work Quantity in a Circular Manhole, first of all measure the circumference of the Circular Manhole. Circumference of the Circular Manhole =2xpixr=piXD (R= radius of the manhole,D=Diameter of the manhole)

Second multiply circumference of the Circular Manhole x height of the Circular Manhole x Width of the Circular manhole then you will get the quantity of the brick work in cubic meter.

Leave a Reply